On my trip from Fort Myers to Jacksonville last year, I ran into issues with the engine overheating. The shop in Fort Myers that fixed the transmission also did a temporary fix on the heat exchanger where the cap fits onto the top of the heat exchanger. The cap connection had been welded before me buying the boat, so having a second weld was far from optimum. Also, I think there were broader issues internally as I kept losing coolant even before the hoses came loose from the heat exchanger in Biscayne Bay. I continued the trip, four days along the coast of Florida, without an engine… It is a sailboat after all.

Parts, like the heat exchanger, are difficult to locate for the Perkins 4-154s. Trans Atlantic Diesels, Inc carries a range of diesel parts including some of the hard to find Perkins parts. The heat exchanger was $1650 to replace.

For those who aren’t boating people, a heat exchanger is like a radiator on your car. The internal circulation system moves coolant in and out of the engine block. Raw saltwater is brought in through a thru-hull, this is passed through the heat exchanger absorbing the engine heat. The raw water is then passed out through the stern of the boat with the exhaust.

Heat Exchanger Removal

Taking out the heat exchanger is pretty straightforward. Eight nuts hold the heat exchanger onto the head of the engine. Four bolts hold the exhaust elbow onto the rear of the exchanger. Then it’s just a few hose clamps, and it slides right out. That was the easy part…

Once I had the heat exchanger out, I realized that since the alternator, which was a ball of rust, sits under the heat exchanger it would be a good idea replace that while I was there. Unfortunately, the bolt holding the alternator in rusted to the spacer. I had to order a Dremel tool to cut the bolt in place. Coupled with the fact that I’m not an enthusiastic diesel mechanic, having to stop to order parts or tools would cause the project to drag out for months.

All The Extras

As Pomaika’i is a dead man’s boat, I don’t have a previous owner I can go back to for details such as when the last time things were replaced. I decided now was a good time to replace the impeller in the raw water pump, replace the raw water strainer, and all the related hoses. Well, I wasn’t planning on replacing the hoses, but in removing them from the raw water strainers for the engine and generator, I found that they had corroded to the thru hulls. Even when I cut the hoses in half, I still had to use a large screwdriver to pry them off the thru hulls. Such is life when you’re fixing a 40-year-old boat.

The engine raw water strainer, a large plastic bucket with a filter inside to keep things like fish out of the boat, was black (couldn’t see inside) and the lid was seized. I replaced this with a new strainer. Double clamped all new hoses on the thru hulls, and now we’re starting to get somewhere.

I sanded off the rust on the pulleys and some of the engine surfaces. I then painted these surfaces to hopefully arrest the rust. I have a lot of higher priority projects right now but may come back and address this issue more in depth when I get the other systems operational.

Installing The Heat Exchanger

After working through all the issues with project scope creep, reinstalling the heat exchanger was rather simple. Same eight nuts on the head, four bolts on the exhaust elbow, and reclamping the hoses. Other than the nuts being challenging to get a socket on, the actual heat exchanger work was easy.

Next Steps

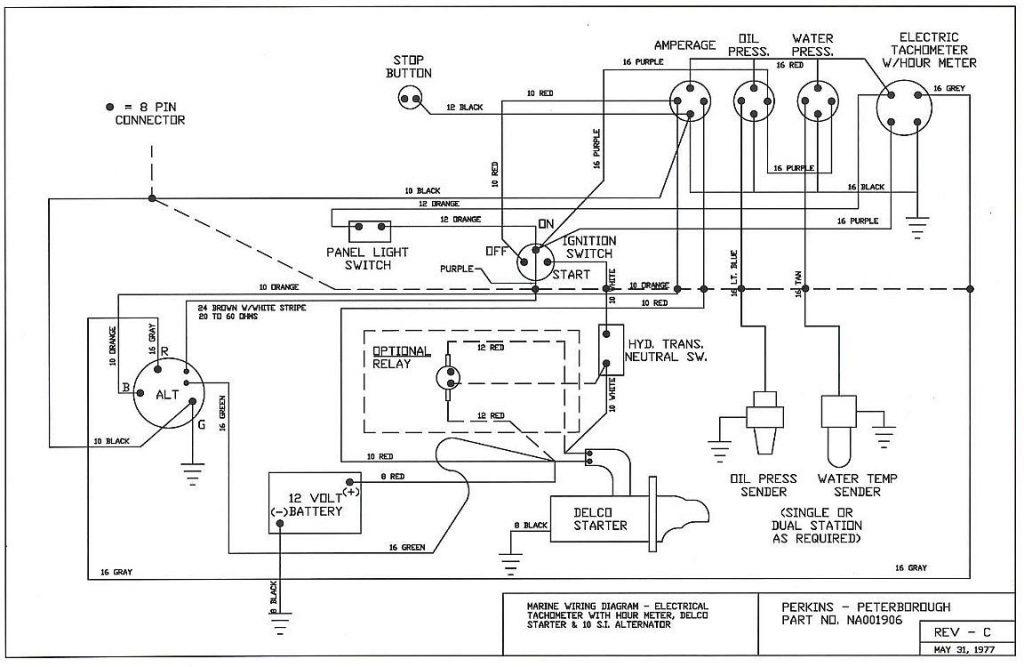

I’m dealing with a lot of corrosion in the electrical system and re-doing all of it in the boat. The next step is to rewire the engine electrical harness connecting the ignition and all the sensor gauges at the helm station. I can’t locate a pre-made harness so I’ll be building one from scratch following this schematic.

[…] Biscayne Bay. Half way down the runway the engine started to overheat (read about my replacing the heat exchanger). I shut down feeling very frustrated but decided I would sail from this point to Jacksonville. I […]